Retrofit of an existing Oral Solid Dosage facility to handle a potent product.

Project Scope:

The client required a collaborative engineering partner with manufacturing capabilities to develop containment systems for entering and exiting several process suites, local exhaust ventilation for several processes, and re-engineer a potent particulate collection system while not compromising material process flow throughout the facility. AEC installed five modular gown/degown suites, a screw-fed potent compound removal and collection system for use with the existing dust collection system, and custom hoods for weighing and dispensing. AEC was intimately involved in all phases of this project and provided a 'best practices' approach to solving this client’s variety of containment challenges.

CLIENT TESTIMONIALS

"We were very impressed with AEC’s creative problem solving methods. Their experience with the design of engineering controls was obvious from the start. They also worked under an exceptionally aggressive schedule and helped with other projects while on-site."

Project Highlights:

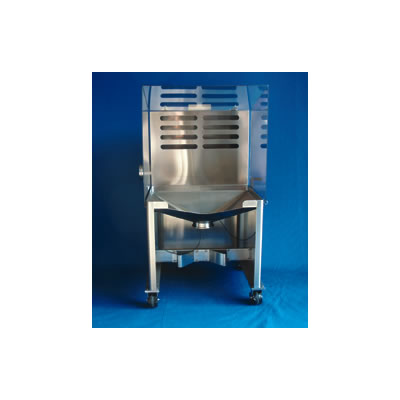

- Custom weighing and dispensing hoods.

- Custom mobile, modular gown/de-gown suites.

- Screw-fed potent compound removal and collection.

- Air entrainment devices.

- Collaborative design effort.